High-G-Light Line

The High-G-Technology is the groundbreaking solution for cleaning pulp suspensions and process water in the pulp & paper industry. Whether for new installations, retrofits, or extensions of existing systems, the High-G-Light Line impresses with a drastic reduction in fiber losses, the targeted removal of contaminants such as stickies, wax, and styrofoam, as well as efficient removal of spinning components. This creates the optimal foundation for sustainable and high performance processes in modern paper production.

Application

The High-G-Light Line stands out due to its versatile application in the paper industry. It reliably separates even the finest light contaminants and is ideally suited for stock preparation, the approach flow system, and the optimization of fiber rejects. Its high efficiency not only significantly enhances pulp quality but also sustainably reduces fiber losses.

Revolutionary Technology for Maximum Efficiency

Compared to conventional hydrocyclones, the High-G Technology employs an innovative design with precise and stable flow patterns. This results in maximum efficiency with minimal fiber thickening and outstanding fiber recovery rates. Thanks to its high selectivity for impurities, reduced clogging tendency, and exceptional wear resistance, ECOFARIO sets new standards in the cleaning of pulp suspensions and the optimization of industrial processes.

The Perfect Solution for Every Process

The High-G Technology allows for flexible use as a standalone tail stage or as a multi-stage cascade in full-flow operation. The system design ensures peak performance even with frequent changes in paper grade and raw materials.

Sustainability at the Highest Level

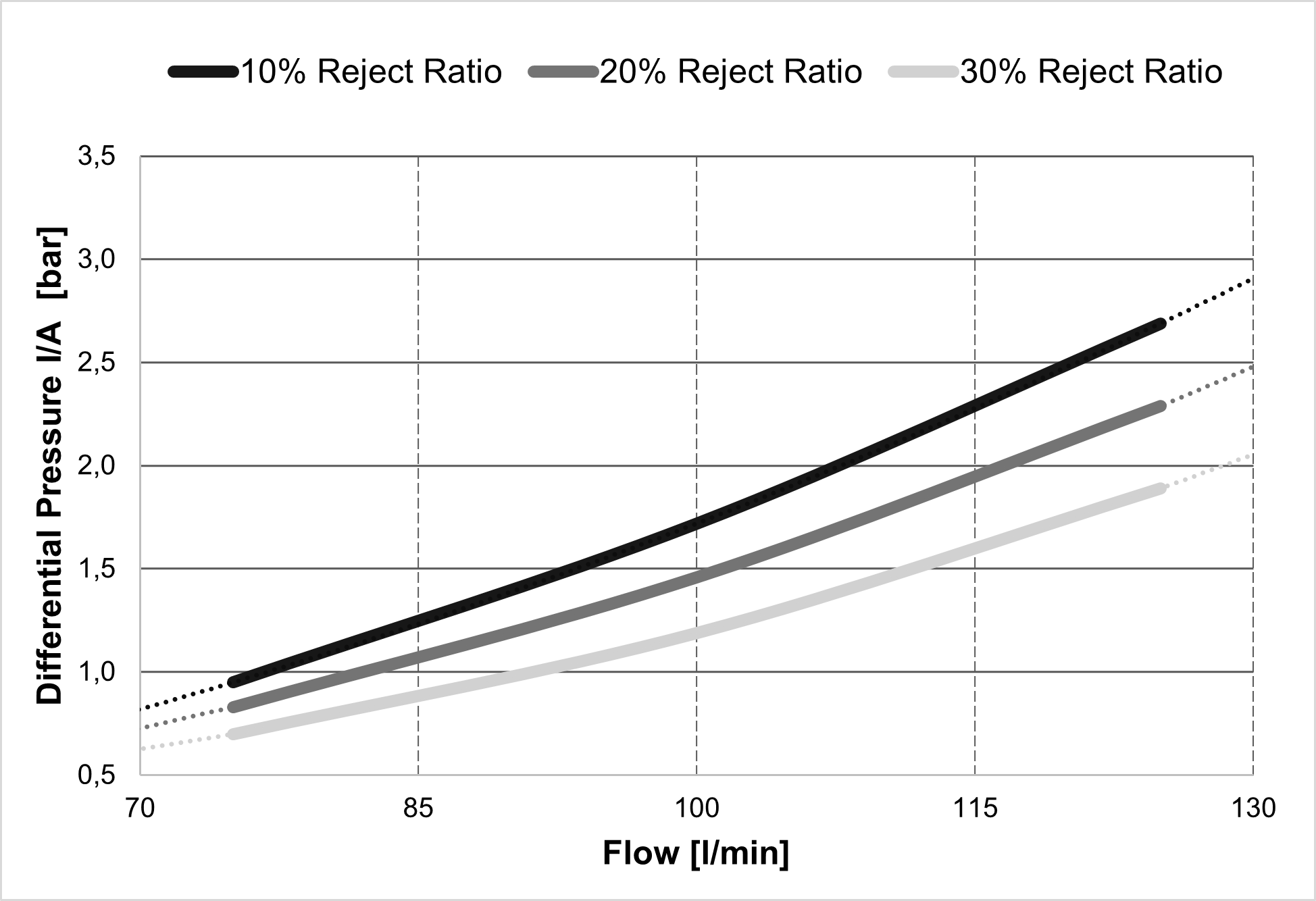

Top-quality components guarantee long operating times, minimize maintenance efforts, and reduce additional service costs – a decisive advantage for an optimized CO₂ footprint. With an extraordinarily low specific energy consumption, resource usage is reduced to an absolute minimum. Additionally, the modular design enables a straightforward plug-and-play installation. Through individually adjustable flow rates and reject ratios, the High-G Technology achieves maximum efficiency with the lowest possible energy and material consumption – a clear win for both economic efficiency and the environment.

Advantages

Excellent efficiency

Low specific energy consumption

Extremely wide consistency range

Minimal fiber thickening

No cone and/or reject dilution

Exceptional durability

Optimized CO₂ footprint

Attractive ROI in the treatment of fiber rejects

Technical Data / 1“

Separator Material 1.4404 / PE-UHMW

Maximum Pressure [bar] 8

Maximum Temperature [°C] 95

Pressure Drop (Inlet–Accept) [bar] 1.2

Inlet Flow Rate [l/min] 100

Minimum Accept Pressure [bar] 0.5

Maximum Inlet Consistency [%] 2.0

Technical Data / 2“

Separator Material 1.4404 / PE-UHMW

Maximum Pressure [bar] 8

Maximum Temperature [°C] 95

Pressure Drop (Inlet–Accept) [bar] 1.1

Inlet Flow Rate [l/min] 400

Minimum Accept Pressure [bar] 0.5

Maximum Inlet Consistency [%] 2.5