High-G-Technology Supports Efficient Wastewater Treatment And Microplastic Removal

Advanced hydrocyclone design combines effluent purification with resource-efficient operation

Increasing environmental regulations and ambitious sustainability targets are placing growing demands on wastewater and effluent treatment in the pulp and paper industry. At the same time, mills are under pressure to reduce the environmental footprint of their operations without compromising efficiency.

ECOFARIO’s High-G-Technology provides an effective solution for wastewater and effluent treatment by combining high separation efficiency with low energy consumption. Based on optimized flow patterns and a defined flow reversal, the technology enables reliable removal of fine particles and contaminants across a wide range of operating conditions.

In wastewater applications, High-G separators have demonstrated particularly strong performance in the removal of microplastic particles and non-biological suspended solids. Industrial installations report microplastic removal rates exceeding 85% in a single pass, contributing significantly to improved effluent quality and supporting compliance with current and future regulatory requirements.

Thanks to its modular and compact design, the High-G-Technology can be integrated into existing wastewater treatment systems with minimal effort. This allows mills to enhance effluent treatment performance without extensive structural modifications or significant additional energy demand.

By combining effective wastewater purification with long service life and low operational costs, ECOFARIO’s High-G-Technology supports paper producers in meeting environmental requirements while maintaining sustainable and economically efficient mill operation.

More information on ECOFARIO technologies is available at

www.ecofario.eco/products

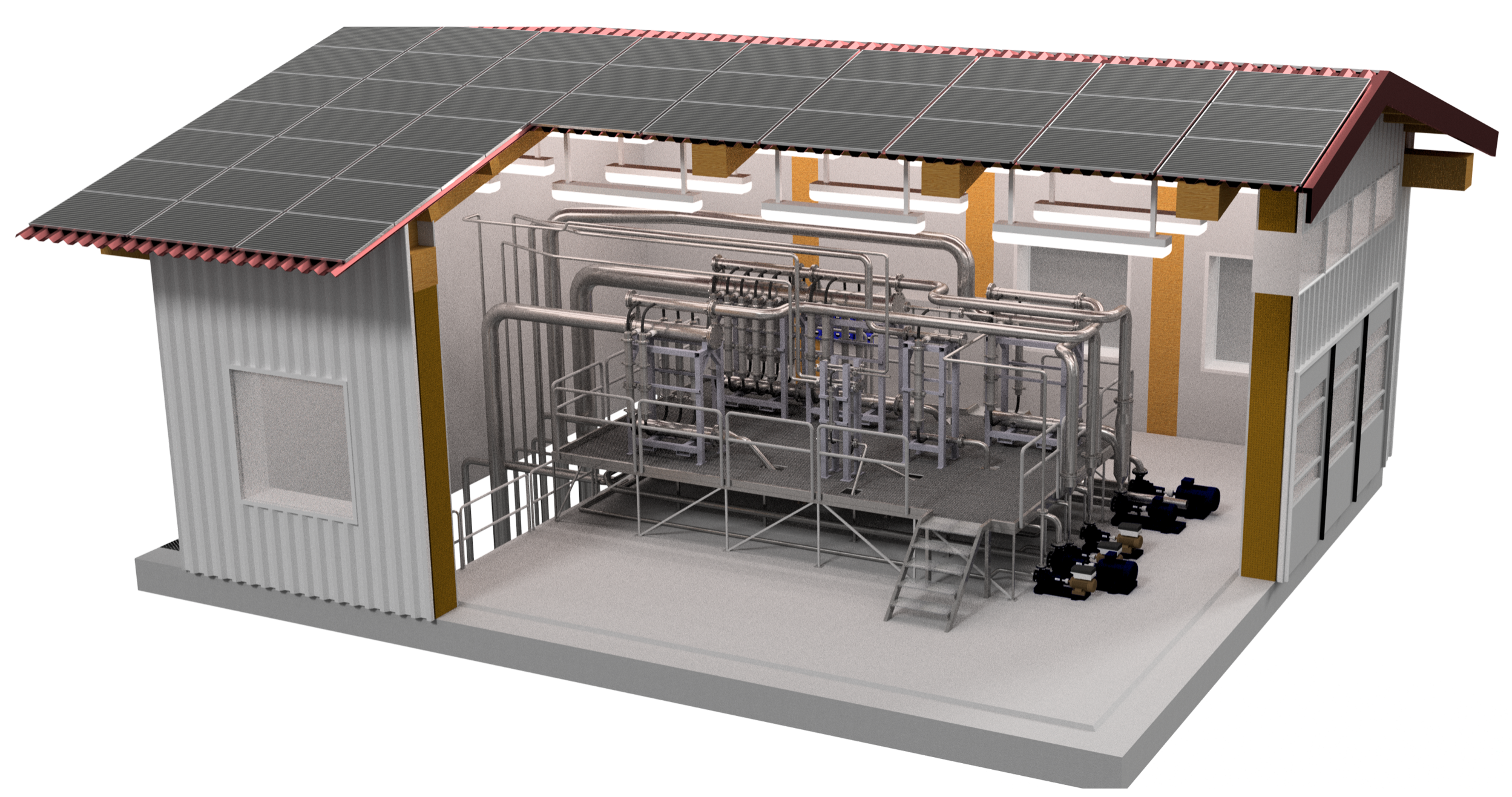

Microplastic removal plant for wastewater treatment using ECOFARIO High-G-Technology.